Superior Valve Products

Superior Valve Products

316 Equity Blvd.

Houma, LA 70361

ph: 985-879-3888

fax: 985-879-3846

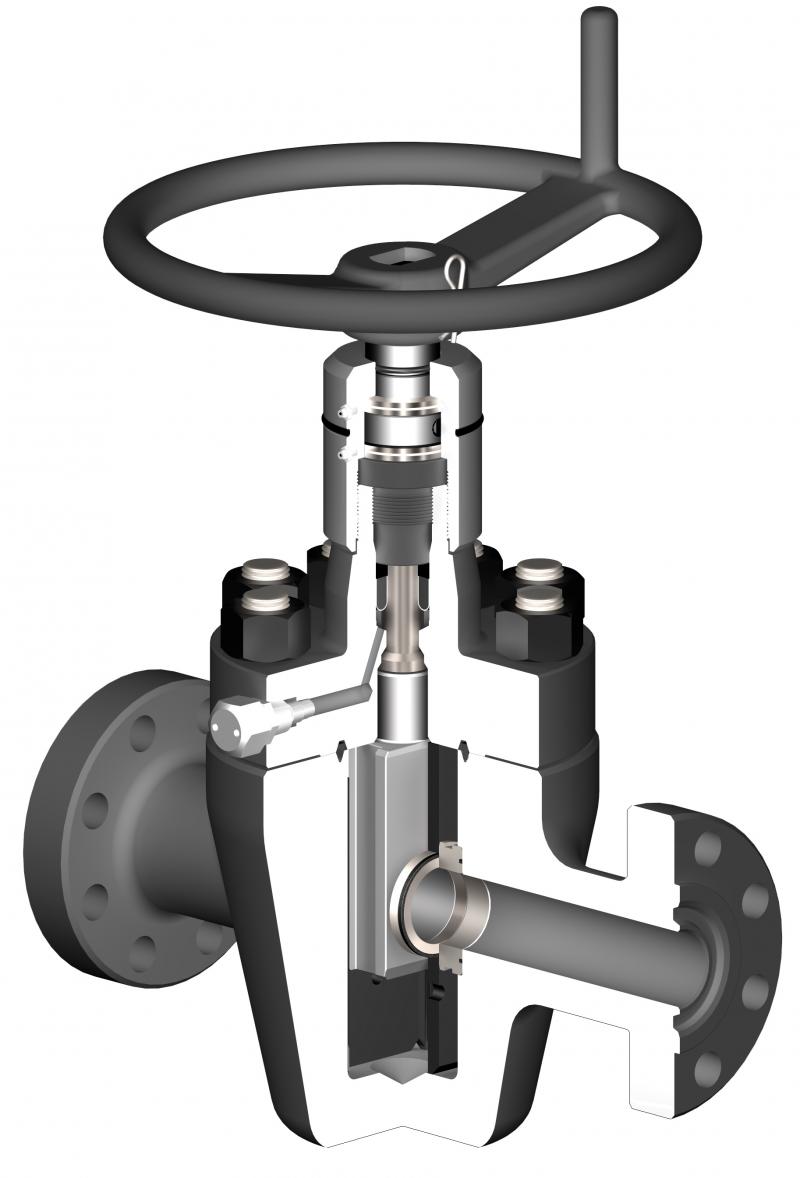

OMNI Model "FS" (CIW Model "FC") Gate Valve

Introduction:

Omni Model FS (CIW Model "FC" interchangeable) forged-body slab gate valves are designed for oil and natural gas wellhead, manifold or other critical service applications with operating pressures from 10,000 to 15,000 psi. All Model FS slab gate valves are API 6A 20th Edition monogrammed equipment and are available in bore sizes ranging from 1-13/16” through 4-1/16”.

Features:

Operating Temperatures

Model FS valves are available with API 6A Temperature ratings of -50 F through +650 F. Valves for API Temperature ratings of X and Y are pressure de-rated as required per Annex G of API 6A 20th Edition.

Slab Gate

The single piece slab gate is field-replaceable and provides the valve with full bi-directional sealing capability at both high and low pressures.

Seat Design

The standard gate to seat and seat to body sealing interface is a two-piece design consisting of a seat ring and a body bushing, assisted by inserts in the rear of each piece. Metal-to-metal gate to seat interface is standard. Metal inserts are used for high-temperature applications.

Packing Design

Stem packing is replaceable and assisted by an anti-extrusion ring. This ensures efficient sealing for the life of the valve. Graphite packing is used for high-temperature applications.

Body Lubricant

All Model FS valves are shipped with body filler grease appropriate for the material class and temperature rating of the valve to ensure smooth operation of the valve under pressure and to prevent corrosion during storage prior to deployment.

Grease Fittings

The valve body may be lubricated through the grease fitting provided in the valve bonnet. An in-line check valve is provided behind the grease fitting to ensure a unidirectional flow. All fittings meet the requirements of NACE MR0175.

Exposed Bolting

All exposed bolting meets the requirements of NACE MR0175. Full Through Conduit Bore The full through conduit bore provides for smooth flow with minimal turbulence. It also provides an unobstructed passage for well intervention tools.

NOTE: All Model FS valves are drift tested in accordance with API 6A 20th Edition requirements.

Copyright 2011 Superior Valve Services. All rights reserved.

213 Gemini Ct.

Houma , LA 70360

ph: 985-879-3888

fax: 985-879-3846